Operation, Maintenance & Inspection of Rotating Machinery.

We offer our pump & motor maintenance and repair service both to contracted customers and customers not on contract, according to the specific needs of each client. Our experienced technicians have gathered a wealth of experience in handling, repairing and maintaining pumps of all types and sizes.

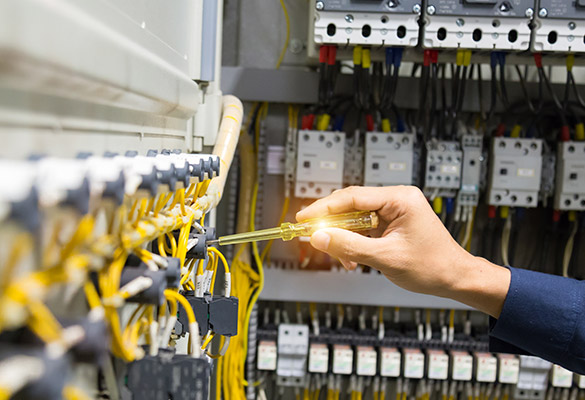

Repair and Parts Replacement of Pump and Motor, Control Panel, Bearings and Mechanical Seal and maintenance of Pumping Systems. Our services include free consultations and accompanying quotations according to our evaluation of the specific client requirements. Our aim is to offer a comprehensive solution which will fully meet the needs of our customers, facilitated by a strong technical team with the required expertise to guarantee a successful implementation of the solutions offered together with expert advice to solve any remaining challenges regarding future handling.

We have extensive experience with Pump Maintenance and repair from many years.

We cater to our Clients' unique M&E requirements and it may range from full-time on-site support or periodic inspections and maintenance. The maintenance may include planned, preventative maintenance contracts, fault finding, regular repairs and a 24-hour emergency and reactive services. We provide Mechanical and Electrical Maintenance Services including Electrical Inspection and Testing, Portable Appliance Testing, Emergency Lighting Testing, Life System Testing.

We provide essential M&E maintenance to provide conditions that ensure a safe and efficient working environment for the occupants to allow them to achieve maximum performance.

We offer cooling tower maintenance and repair services in annual contract basis and provide Preventative maintenance service, Fan and belt repairs, Pillow block bearings service,

Motor repairs, Cooling tower pump repairs, Frequency drives service, Equipment change out.

We pride ourselves in providing highly qualified and skilled HVAC technicians specialized in preventative maintenance contracts that are specific to your cooling tower needs.

Spring United can help to reduce the chances of costly replacement of the Air Handling Units by regular maintenance including filter changing, anti-corrosion coating to drip tray and floors, replacement of panel locks and resealing, the replacement of drive belts and pulleys, fan replacement and bearing replacement, heating/cooling coil replacements.

Our team of experienced surveyors have an in-depth knowledge of the operational and maintenance requirements of all types of AHUs.

Wet scrubber function by driving the generated gaseous stream through a scrubbing solution prior to its atmospheric discharge. Spring United applies the inexpensive scrubbing solutions for proper, regular scrubber inspection and maintenance including PH calibration, belt & pulley check with alignment, applying grease, impeller, laser alignment, vibration & temperature check. Our service includes regular maintenance of dosing pump unit and scrubber’s electrical panel.